Design and Development of a Temperature Range Stability Control System in the Internet of Things (IoT) Integrated Batik Waste Ozonization Model Process with NodeMCU ESP8266.

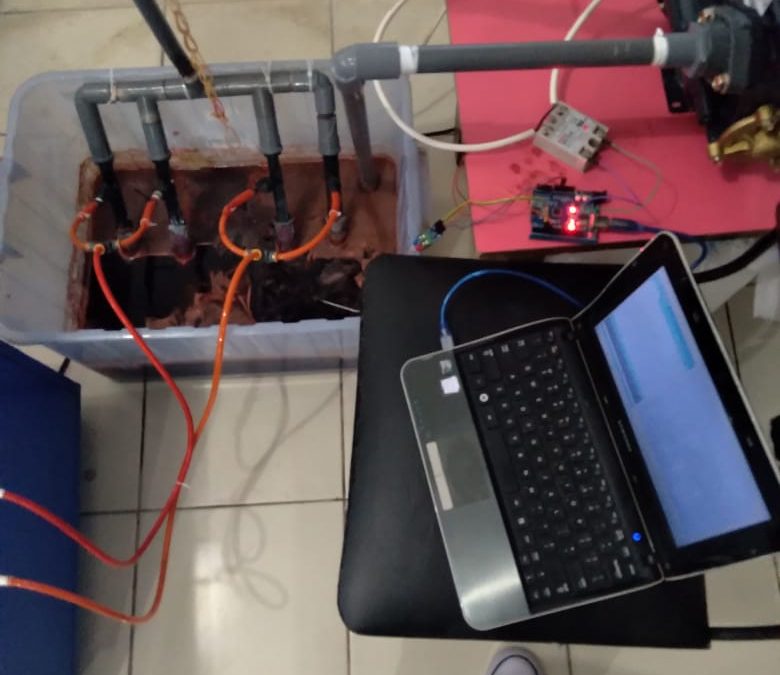

It has been possible to design and apply a temperature control system to the ozonation process of liquid batik waste by integrating it into IoT which aims to make the system possible for remote operation and real-time data retrieval which is useful for simplifying its application. Temperature measurement is carried out with a K-type thermocouple sensor which provides input to the microcontroller so that it can give orders to the relay to control on/off which functions to maintain the temperature range of the ozonation system so that it does not exceed the specified limit. The display of temperature measurement results is carried out through the Blynk application which is integrated through the desktop and mobile. When the ozonation process takes place, it will produce heat in the liquid batik waste which makes the temperature increase within 34.85 minutes, while the time required for the temperature to decrease in temperature is 72.38 minutes. Based on the data analysis that has been done, it is known that the temperature control system in the ozonation process of liquid batik waste can maintain temperature stability which is useful for increasing the efficiency of the performance of the ozonation reaction.

Keywords: Control system, temperature, IoT, ozonation of liquid batik waste.